Print out Instructions

WHEN TO CLEAN:

For Pools: Clean the cartridge(s) when the pressure gauge on the tank reads 8 psi above the initial system pressure. Tip: Measure the psi with a clean pool filter first, and avoid letting the pressure exceed 8 psi over this initial reading.

For Spas: Clean the cartridge(s) when you notice a decrease in water jet performance or when spa features like waterfalls are not functioning as well. This will depend on how frequently you use your spa.

HOW TO CLEAN:

Follow the Manufacturer's Instructions: Begin by referring to your specific manufacturer's instructions on how to safely remove your filters.

Turn off the Power:

For Pools: Turn off the power to your pump and bleed the pressure from the tank before removing its top section.

For Spas: Turn off the power to the spa and release any pressure in the system.

Remove and Rinse the Filters: Take out the filter(s) and hose them off thoroughly to remove dirt and debris. Avoid using high-pressure washers, which can damage the filters.

Deep Cleaning (Optional):

Soak your filters for at least one hour or preferably overnight for a thorough clean.

Use a filter cleaner like Jack's Magic Filter Cleaner for a faster turnaround.

Tip: It's a good idea to have a spare set of filters to use while you deep-clean the first set.

Handling High Bather Loads (Oils, Lotions, etc.): For filters clogged with oils or lotions, soak them overnight in one of the following solutions:

Detergent: Mix 1 cup of detergent with 5 gallons of water.

Trisodium Phosphate: Mix 1 cup with 5 gallons of water. (Always wear waterproof gloves and goggles when handling chemicals.)

Enzymes: Follow the manufacturer's instructions.

Filter Cleaner: Follow the manufacturer's instructions.

Algae-Contaminated Filters:

Soak the filters in a solution of water and pool algaecide for 15-30 minutes. Follow the dosage instructions provided by the algaecide manufacturer. (Always wear gloves and goggles when handling chemicals.)

Rinse Thoroughly:

Make sure to rinse the filters well before putting them back into your pool or spa equipment. Reassemble Equipment: Follow the manufacturer's instructions to properly reassemble your pool or spa system.

SAFETY REMINDER:

Always use gloves and eyewear when working with cleaning solutions. Safety first!

Print out Instructions

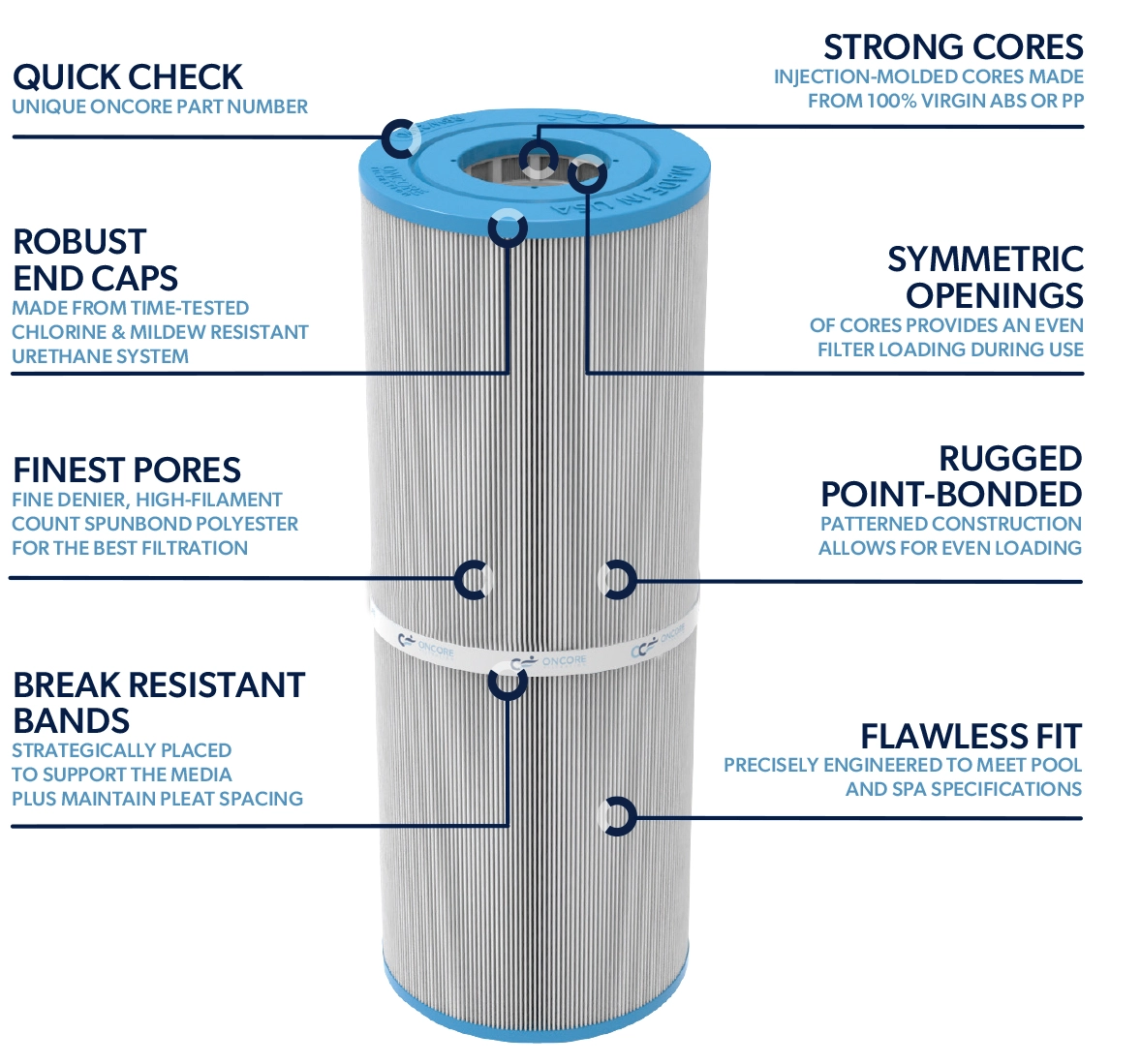

POINT BONDING

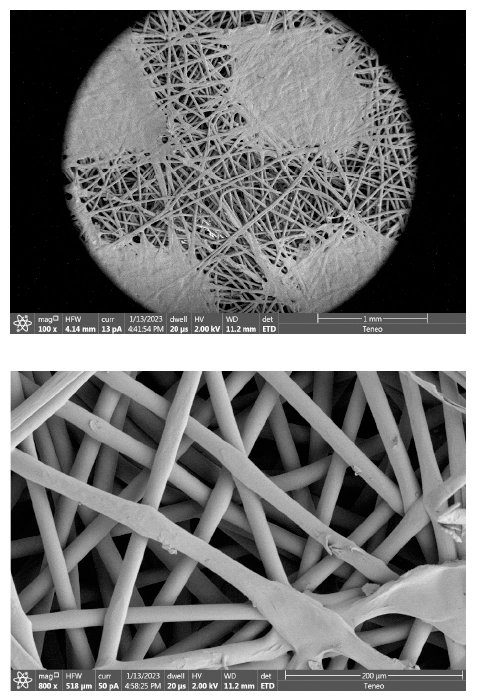

In modern polyester spun-bonded processes, continuous fibers are spun at high speeds and interlock to form a web, becoming the filtration media. To ensure stability, the fibers within this web must be securely locked.

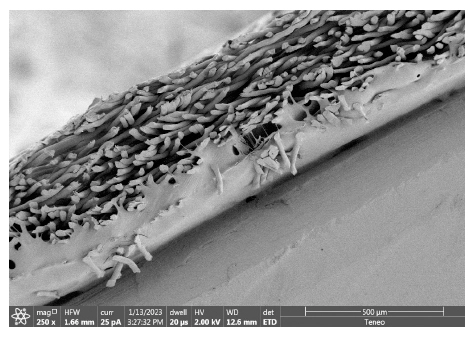

Point bonding achieves this by running the web over a calendar roller with a patterned surface. The raised areas create dimples in the media, forming a strong weld pattern that locks the fibers in place while allowing movement between them, enabling the media to adapt to flow conditions and capture particles of different sizes.

In pool and spa applications, these welds promote filter cake formation, enhancing filtration efficiency over time. As water passes over the surface, it channels around the welds, improving the process.

When the filter becomes loaded (seen as decreased flow in spas or increased tank pressure), it can be removed and cleaned. The consistent weld pattern facilitates debris release, preventing full clogging of the media and simplifying cleaning.

WEB LOFT

OnCore uses low denier, high fiber count polyester media to achieve many crossover points inside the web. This creates more pores of finer consistency, allowing the media to be very efficient at removing debris. Smaller and more abundant pores achieve cleaner water sooner. Studies have shown a faster drop in turbidity (water cloudiness) when using a low denier Point Bonded media. As seen on the cross section of the web, welds on the surface of the media do not penetrate all the way through. This allows the water to travel throughout the loft of the web, working its way out the other side.

The approach of Point Bonded, low denier, high fiber count, high cross- over-point media delivers more fiber surface area than our competitors, allowing us to provide the best filtration in the market.

Print Version